TurboDrop Nozzles ~ Cotton Grower

Cotton Grower Plus, May/June 2001

A MEISTER publication

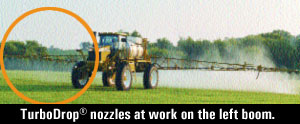

The TurboDrop® nozzle's versatility sets it apart from other nozzles on the market.

Will Smart, president of Greenleaf Technologies, says cotton growers have found the nozzle ideal for applying almost any product.

"They first used it for drift control for herbicides," Smart explains. "However, they quickly found that it gives such good canopy penetration and coverage they now use it for all applications, including burndown, post-directed applications, insecticides and defoliation."

The nozzle is suitable for so many applications because of its unique design, Smart says. The long-wearing ceramic or polyacetyl orifice in the Venturi determines the flow rate. The large mixing chamber gives a very uniform droplet spectrum. The higher speed and larger size of the droplets ensure better penetration depth into the crop canopy.

The nozzle is suitable for so many applications because of its unique design, Smart says. The long-wearing ceramic or polyacetyl orifice in the Venturi determines the flow rate. The large mixing chamber gives a very uniform droplet spectrum. The higher speed and larger size of the droplets ensure better penetration depth into the crop canopy.

Lower Rates

"Another shining place for this technology is the five-gallon rate of Roundup," Smart adds. "Many growers still apply 10-gallon Roundup and more in different parts of the Cotton Belt, but the ones that are really taking advantage of the TurboDrop® are using the five-gallon Roundup. The results are as good or better than what they're used to because they're putting the herbicide where they want to put it. These air filled droplets give them better coverage and quicker control. Consequently, many growers have the ability to cover twice the acres before refilling their tank."

Wide Variety of Nozzles

TurboDrop® nozzles are available in low and high-pressure versions (from 15 to 300 psi), with either poly or ceramic wear orifices. A wide variety of pattern tips (flat fan, off-center, hollow cone, etc.)

Another benefit is the versatility of using different types of pattern tips, Smart says. "For example, in the Mid-South, a number of growers, instead of using the standard 110° tip, switch to one with a narrower angle like an 80° tip which will focus the spray even more for better penetration into a very dense canopy.

"They'll put even spray tips for banding. If you can band a chemical instead of broadcast, you can get another additional savings."

Many Texas and Georgia cotton growers take the Venturi nozzle with a flat fan for their herbicide work, and switch to a hollow cone tip - using the same Venturi to control the flow rate, Smart notes. "This combination gives them that three-dimensional pattern where they want better coverage. They'll also increase the pressure."

It's critical to use the correct penetration and better coverage - without having to use heavy water volumes."

Greenleaf Technologies has been offering TurboDrop® nozzles for six years. Three years ago, they introduced the TurboDrop® XL nozzle, which is designed to better handle lower pressure. "That has become our most popular nozzle," Smart says. "By changing tips, you can actually convert it to a high pressure version as well."