Product Demonstration Video

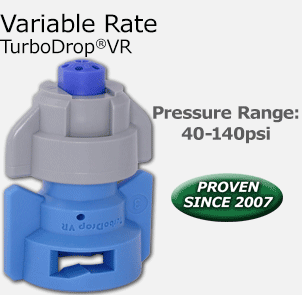

Popular Nozzles from Greenleaf Technologies

- The original low pressure, economical air injection nozzle

- Fits standard caps

- Also available in off-center version

- Excellent for glyphosate application

- No O-ring to break or lose

- Medium droplets for contact chemicals

- Difficult to plug -- Easy to clean

Choosing the Right Nozzle

Venturi Nozzle Overview

Compare the low pressure, medium pressure and high pressure nozzles from Greenleaf and find the one right for your application.

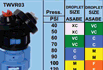

Nozzle Calculator

Reduce drift potential by confirming the correct nozzle size based on your particular flow rate.

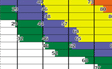

ASABE Droplet Size Classification Chart

Find out where each Greenleaf Nozzle performs best. There is one for your application based on multiple conditions.

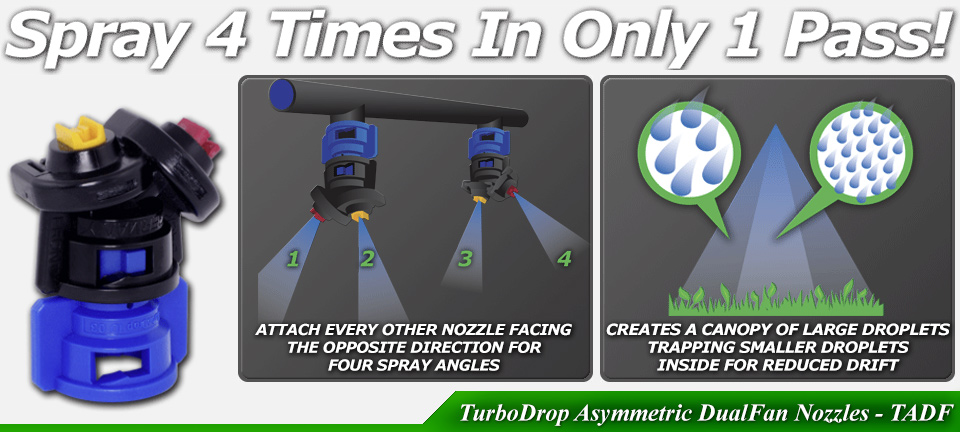

How Turbodrop® Nozzles Work

Turbodrop nozzles use a Venturi system to draw in air. This makes droplets less likely to drift. It’s the proven method trusted by professionals.

Tabulation Charts

Full details on the various sizes of Greenleaf nozzles so you choose the right one for your specific conditions.

Test Data

Beluga Drop Hoses in Corn

This excellent article from Sprayers 101 covers the installation and configuration of the Beluga HoseDrop system. Results show reduced disease in the canopy, which lead to better yields verses overhead spraying as well as the control.

READ MORE

BPDF DualFan PWM Coverage

Greenleaf Technologies' BPDF DualFan nozzles for PWM systems provide more than twice the frontside coverage, and three times the backside coverage for vertical targets when compared to a flatfan spray pattern.

READ MORE

Nozzle Selection for Drones

In drone spray applications where high wind speed is a part of the application platform Greenleaf Technologies' AirMix nozzles bested the competition when compared to TeeJet XR FlatFan as well as the AIXR nozzle.

READ MORE